BamCo®

Our specialized process optimizes the natural feel and inherent characteristics of plant-based fibers, making our signature fabric more comfortable, durable, and with performance features that last for the lifecycle of the garment.

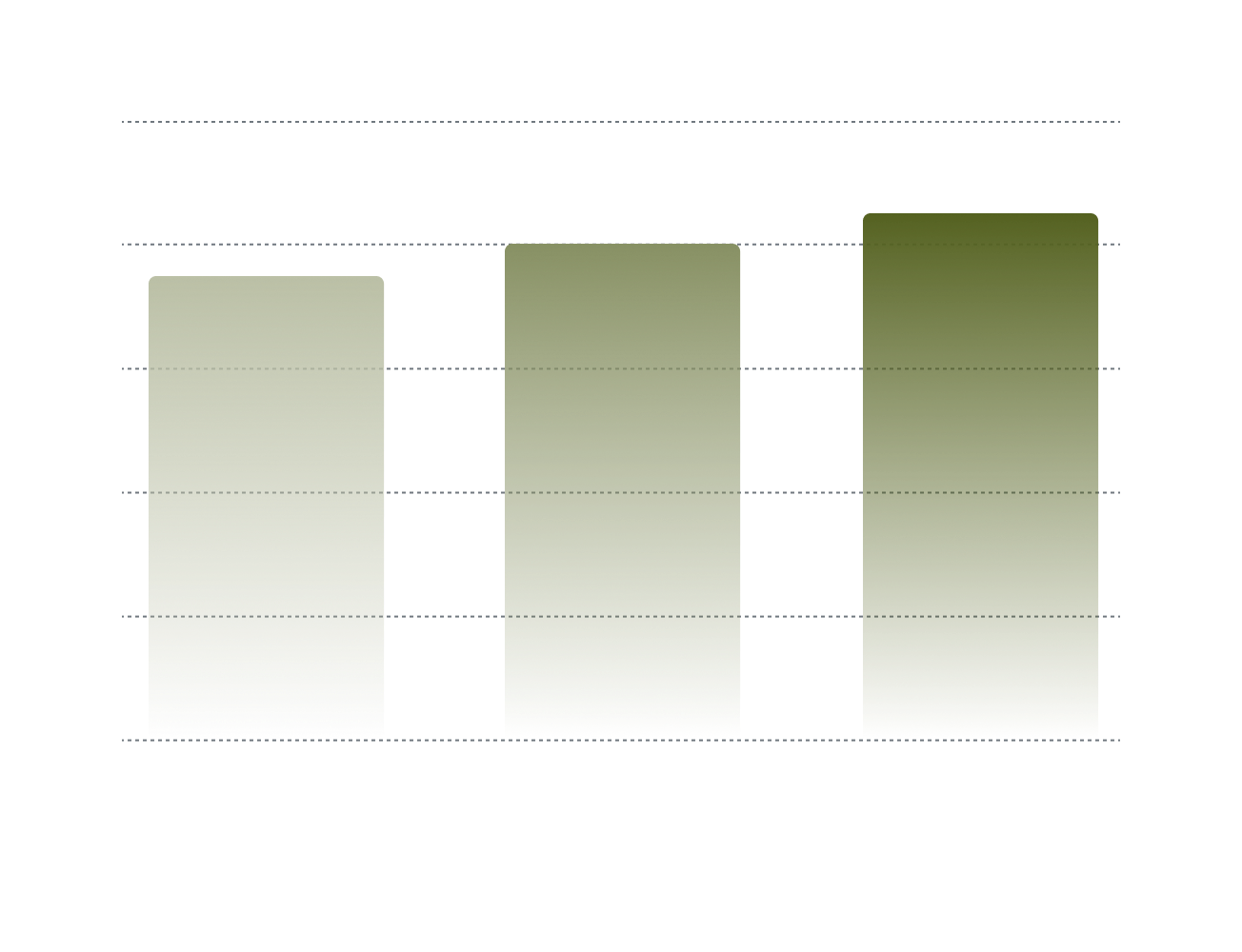

75% of our products

Made from natural fiber-dominant blends (primarily organic cotton).

Our Goal: Always Do Better

We are committed to using at least 85% sustainable (plant-based + recycled) materials in our products by 2025. The path to better is not easy, but necessary. Through continuous investment in original fabric innovation and production methods, we are confident in achieving our goal.

Our Planet

Respect for the environment and a focus on sustainable solutions has been top-of-mind from day one. Apparel production is a complex endeavor requiring the coordination and participation of many people. With 40+ visits to the factory, our co-founders are directly involved in the constant quest to improve and create responsible initiatives.

Our Passion

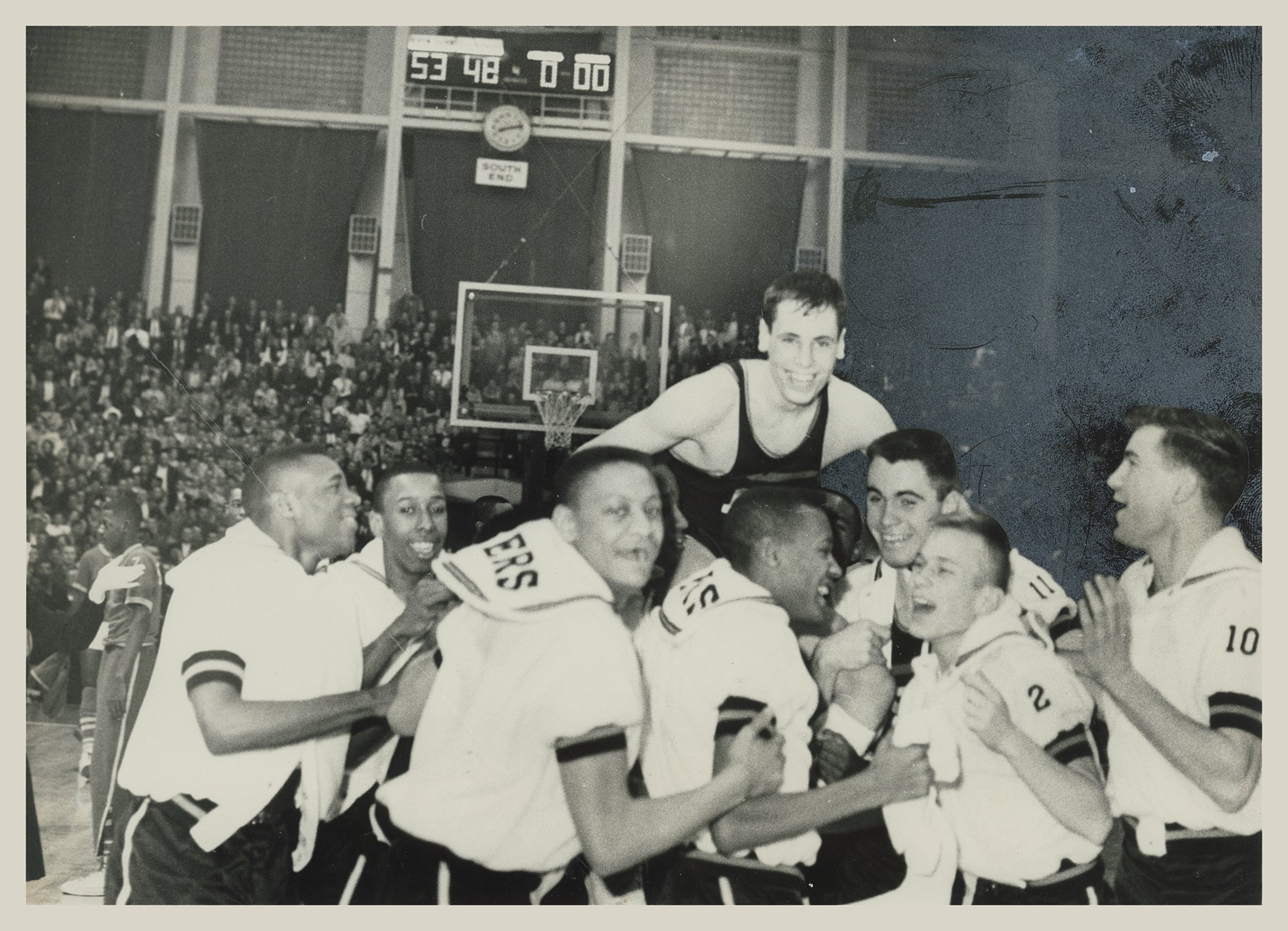

Born from a deep love of sport and an authentic drive to do what’s right, our family-run company maintains one goal: to create the best activewear in the world, for the world.

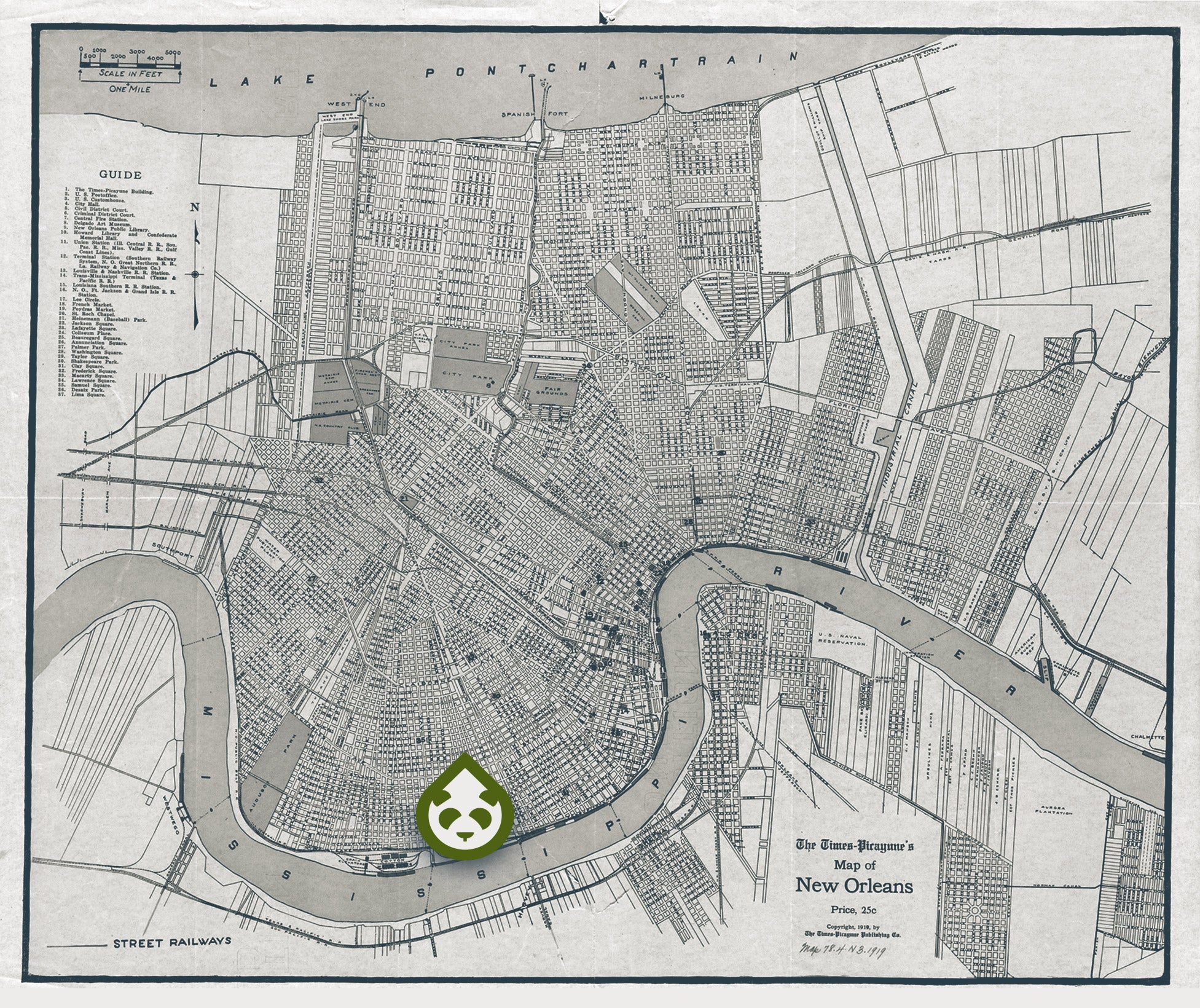

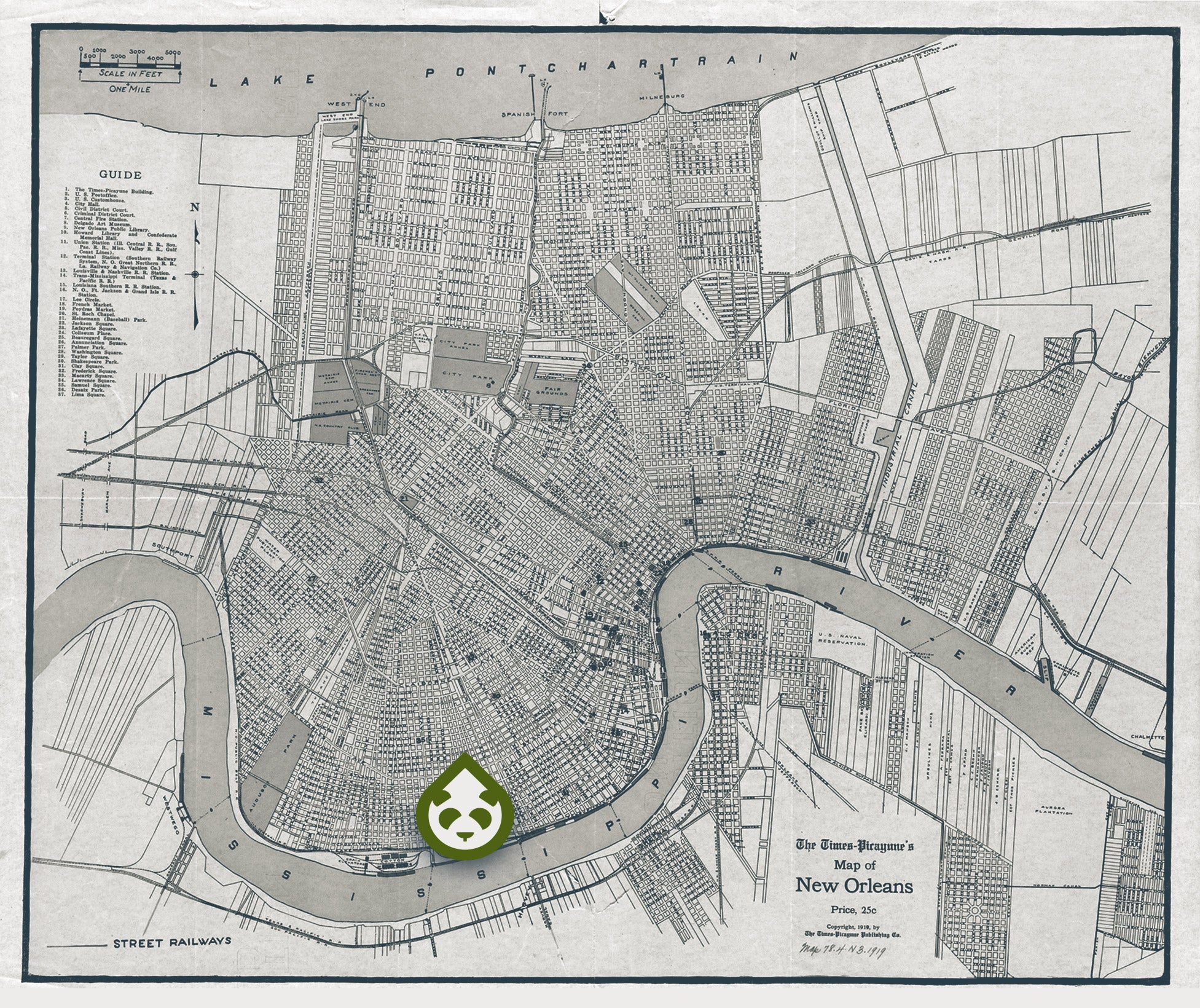

Photo: Al Andrews (Co-Founder and Chairman of tasc) celebrates a victory.

After decades of dedication and constant innovation, we created the tasc brand. From our humble beginnings in New Orleans, to a company that now spans continents, we continue in the pursuit of better: better materials, better processes, and a better future.

Our People

Our search for the right production partner sent our co-founders around the globe where they met a family-owned factory in southern India. 24 years of collaboration, invention, home-cooked meals and birthday celebrations later, we continue to inspire one another and grow together.

From the start, we have been industry pioneers in fair and empowering workplace practices that include:

-

Higher Wages

We provide an 18% higher wages than the local average.

-

Healthcare

Free for all employees and their families (over 500 people).

-

Housing & Food

Subsidized on-site living quarters and meal programs.